Industrial Rectifier

-

BH-Z (K) E (H) S Series of Sealed and High- power Rectifier

Combinating advanced design ideas with successful experience at home and abroad, we can do sealed treatment for the rectifier(AC-DC bus bares, waterways and secondary protection circuit and other sealing processes), design of housing heat exchange, isolation of inside and outside air when operationg, heat exchange between water and wind to the junction of temperature. High degree of protection is suitable for higher level of DC voltage. The idea can be applied to indoor and outdoor design under the harsh environment and extreme temperatures.

-

BH-KE (H) S Series of High-power, Noninverting and Inverse Parallel

Owning to its rational design, mature technology, its adjustable current from 0 to 100 percent,they can greatly increase the safety coefficient, reduce the loaded progression and the number of gear operations, effectively save operating costs, improve current efficiency and finally provide the electrolytic aluminum industry with a stable, secure and reliable DC power.

-

BH-KZX10 series of intelligent thyristor steady flow control devices

The utilization of JM810 NC device has greatly met the requirments of the precise and reliable thyristor units’ steady flow control. The utilization of core unit of the minimum steady flow and design technology of all digital, dual-channel redundant and hot standby steady flow system has ensured the long-term operation. Self-diagnosis and intelligent control and protection process of real-time system, realization of synchronizing signal, abnormal feedbacks of AC-DC, overcurrent of the unit, malfunction of the trigger, dual-channel monitoring, automatic detection and intelligent protection processing have substantially improved the reliability of overall system. Fully functional PLC control system has improved the equipment’s operating safety and the effectiveness of protection and control.

-

Overall modulation screen of BH-ZX110 Rectifying Series

Fully digitized series of overall modulation system, equipped with world-class brand PLC and gathering strong network communication functions: it can realize the establishment of single-wire, dual-network, tree network, ring network and other various networks.

-

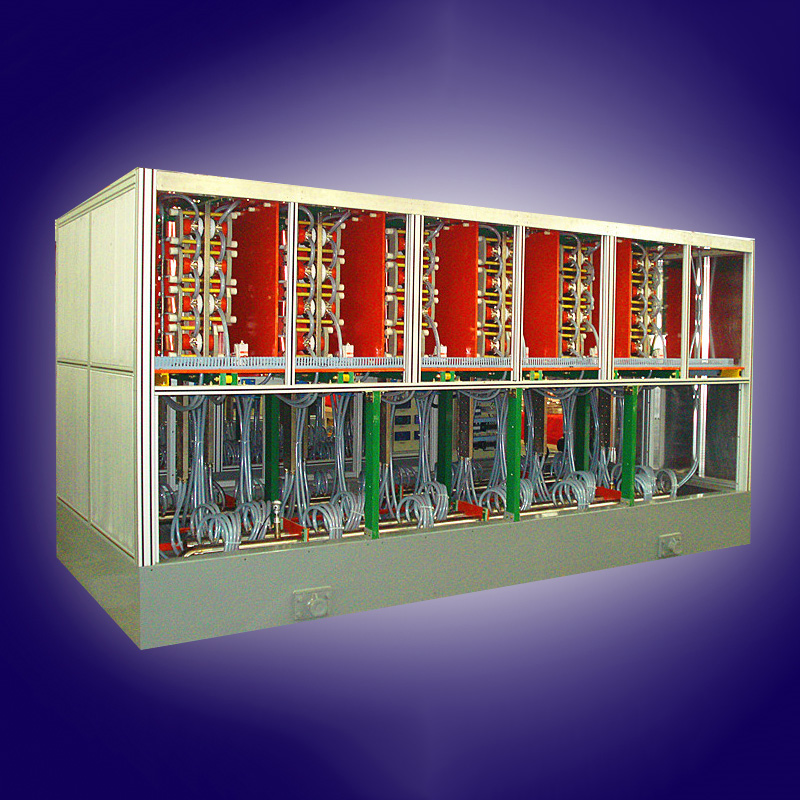

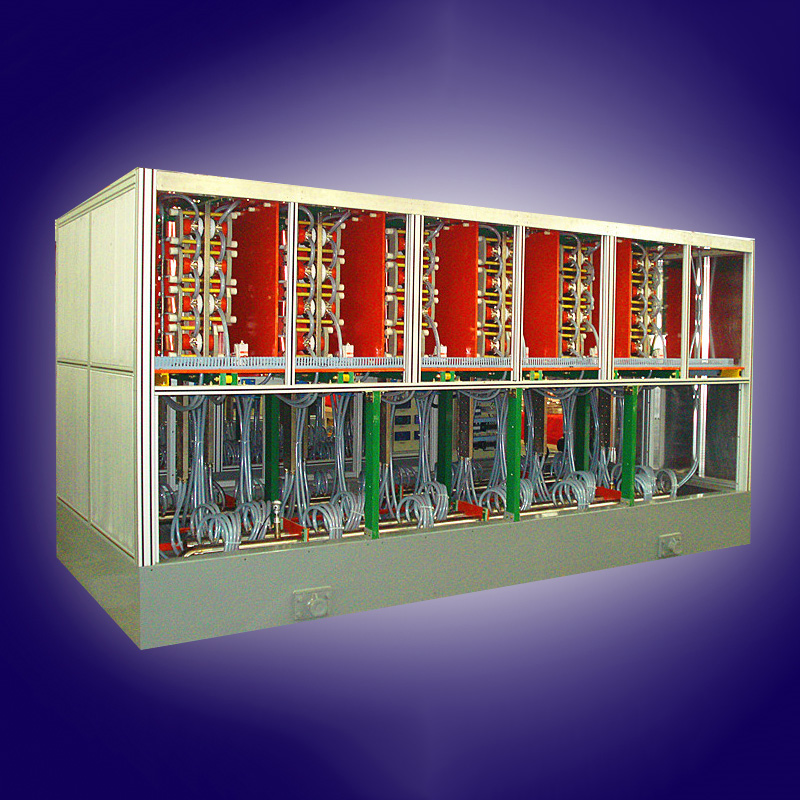

BH-ZE (H) S series of horizontal and high- power rectifier

good heat dissipation, low noise, convenient maintenance, high-voltage, high safety performance, large coefficient of average current of elements , low losses, simple waterway, low electrical corrosion, low noise and convenient maintenance.

-

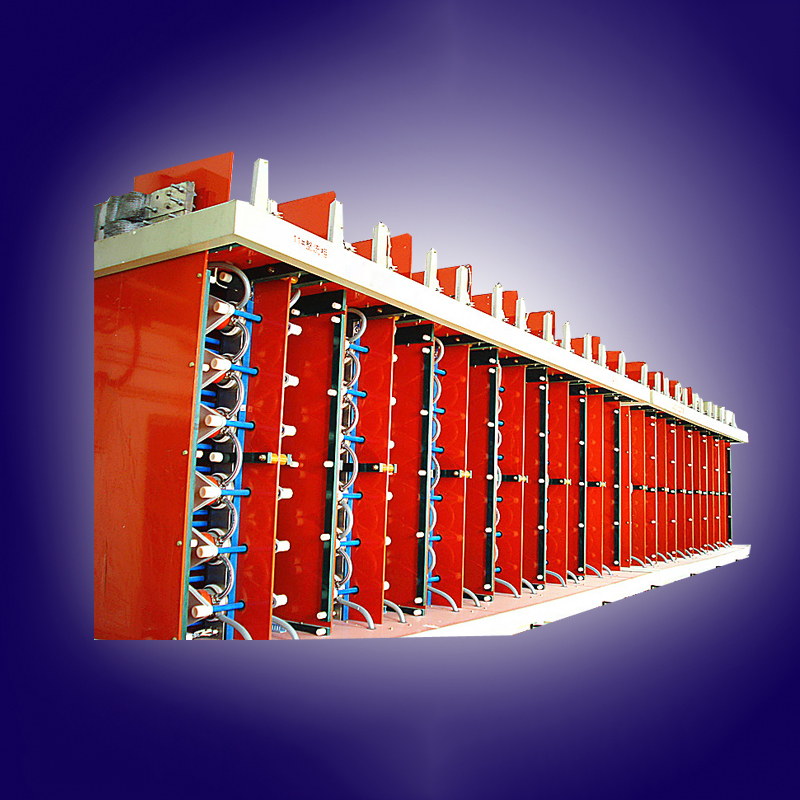

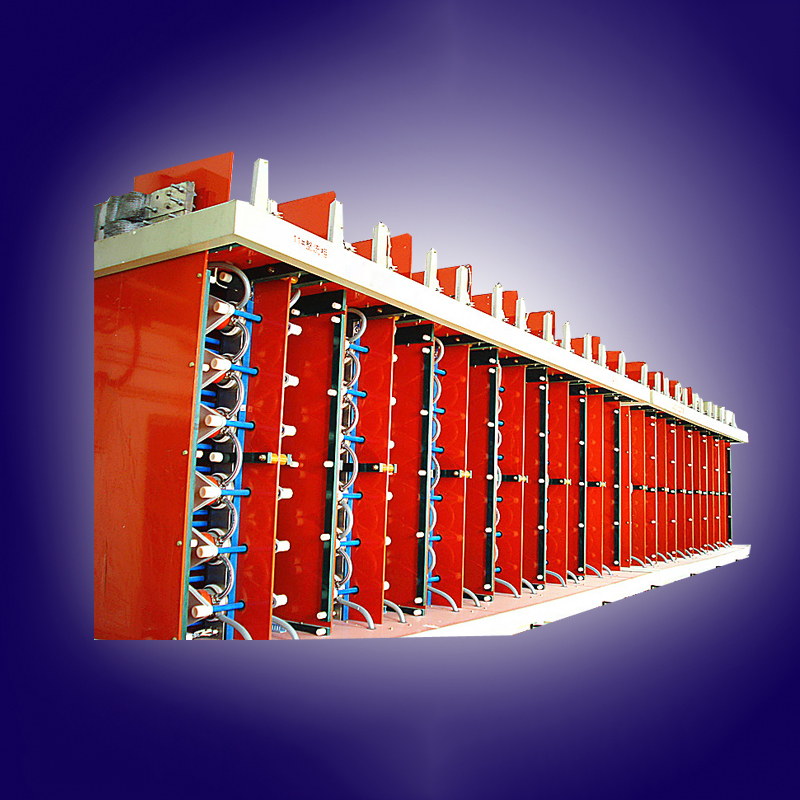

BH-ZE (H) S Series of High-power and Hierarchical Diode Rectifier

Rectifier Cabinet with Brand New Structure not only possesses the strengthes of that which is not noninverting and inverse parallel structure, but also has some new technical features, this structure meets the new requirements of rectifying means in the electrolytic aluminum industry (high level of series of voltage) and makes up defects of some traditional vertical structures (noninverting and inverse parallel structure).

-

BH-ZZX10 series of intelligent and saturated reactor steady flow control devices

Fully digitized and saturated reactor steady flow system, the latest generation of digital steady flow technology, which is equiped with world-class brand PLC and HMI is applicable to all kinds of saturated reactors. HMI human-machine interface has powerful functions, convenient and friendly, simple operation. Flexible network communications facilitate the realization of the entire integrated automation.

-

BH-KE (H) S series of High-power and Hierarchical Thyristor rectifier

Gathering the Characteristics of thyristor and hierarchical structure, rigorous technology, complete protection system, advanced control technology and perfect structure. It is suitable for a variety of large DC power supply and special DC power supply (such as the utilization of lone-grid power supply mode of the isolated network).

-

BH-ZE(H) S Series of Self-supporting and High-power Rectifier

Self-supporting structure, less panel and metal support, good heat dissipation and low losses. Element row utilizes the way of symmetrical pressure to decrease the possibility of corroded components and improve the coefficient of elements’ average current.

-

BH-ZL-200 series of large-scale rectifying and intelligent network monitoring system which is based on fieldbus

Intelligent network monitoring system (host computer integrated control system) consists of three-part hardware—a computer, a programmable controller and a communication cable connector.It is made by integrating advanced computer, control and communication technologies based on the man-machine interface, which can realize the measurement and control of rectifier equipment’s main operating parameters and status, possessing the functions of screen display and printed output.